Chengxun fruit and vegetable processing products, from material selection, production, quality inspection to after-sales service, are strictly implemented in accordance with the appropriate plan to ensure that customers are willing to choose to cooperate with Chengxun again and again because of Chengxun's excellent product quality and good after-sales service. The young Chengxun also hopes to realize his dream of becoming a century-old enterprise through this way of development.

DJ2 type double channel beater

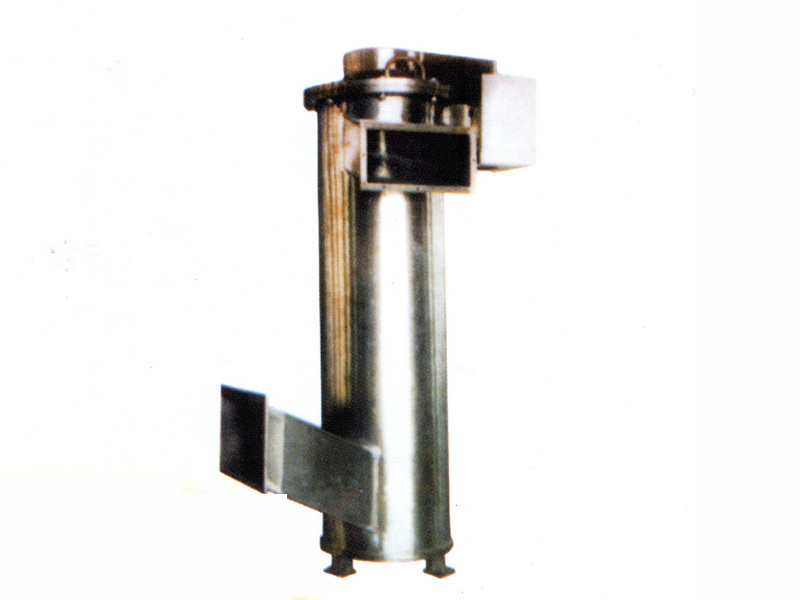

CPS series squirrel cage crusher

LYJ series continuous precooking machine

GXJ series roller bar fruit inspection machine

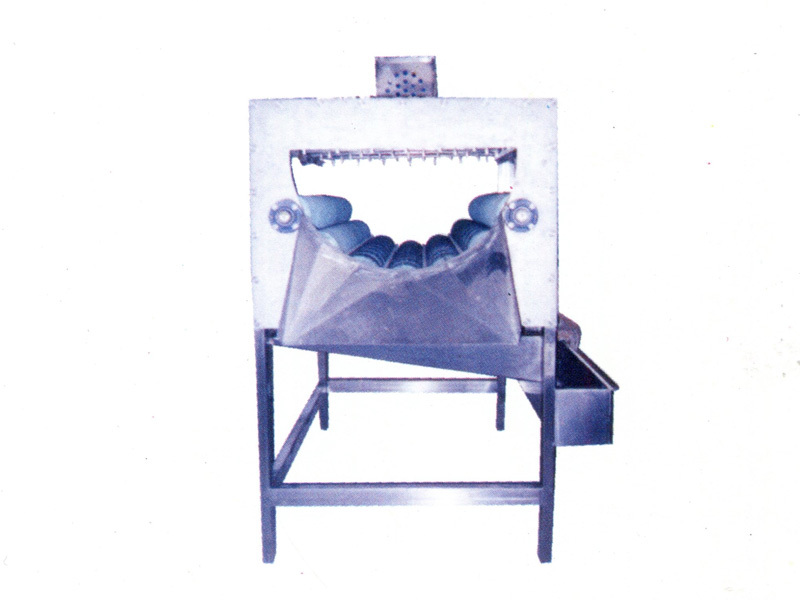

MQJ series brush peeling machine

MXJ series brush fruit washing machine

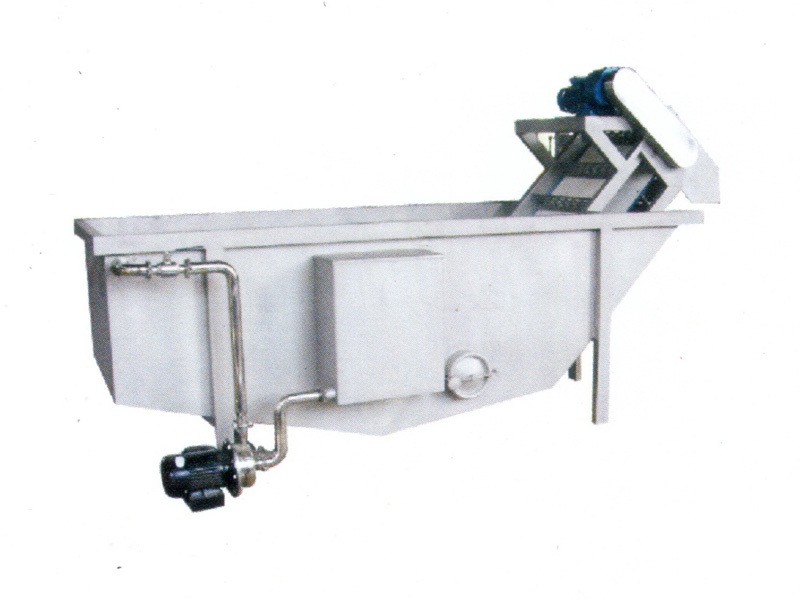

CXJ series bubbling fruit washing machine

CXJ series puller type fruit washing machine

Telephone:

Mailbox:

Address:

Xinqiao Industrial Park, Jingjiang City, Jiangsu Province

Fax:

+86-523-84320678,84310678

Online message

Copyright©2023 Jiangsu Chengxun Technology Co., Ltd.